Step Drill Bit vs. Countersink Bit: Understanding the Key Differences

When it comes to drilling and preparing holes for screws or bolts, two specialized tools often come into play: the step drill bit and the countersink bit. While both serve crucial roles in projects involving wood, metal, or plastic, their functions, designs, and uses are quite different. Understanding the distinction between these two tools will help you choose the right one for your project, ensuring smooth, professional results.

The primary difference between a step drill bit and a countersink bit lies in their intended purpose. A step drill bit is designed to create holes of various sizes with a single tool, while a countersink bit is used specifically to create a conical hole at the entrance of a pre-drilled hole. This countersink allows the head of a screw or bolt to sit flush with, or slightly below, the surface of the material.

Step drill bits have a unique, tapered design that allows them to drill multiple hole sizes without the need to switch between different bits. The bit features a series of steps, each increasing in diameter, so as you drill deeper into the material, the hole gets progressively larger. This versatility makes step drill bits ideal for tasks where different hole sizes are needed, such as drilling through thin metals, plastics, or even some woods. They are often used in electrical work, sheet metal fabrication, and other applications where precision and efficiency are key.

Step drill bits are particularly well-suited for working with thin materials. For instance, if you're drilling through sheet metal, a regular twist drill bit might cause tearing or distortion around the hole. The step drill bit, however, creates clean, round holes with minimal damage to the material. This is because the stepped design allows for a gradual increase in hole size, reducing the force needed and providing a smoother drilling experience. Additionally, many step drill bits are designed with flutes that help to remove debris as the hole is drilled, which reduces the risk of overheating and extends the life of the bit.

In contrast, a countersink bit serves a much more specific function. After drilling a hole for a screw, a countersink bit is used to enlarge the opening slightly, creating a conical shape that matches the angle of the screw head. This allows the screw to sit flush with the material's surface, creating a smooth finish. Countersink bits are commonly used in woodworking, cabinetry, and general construction when a polished, professional look is desired. They prevent screws from protruding above the surface, which can not only look unsightly but also interfere with the functionality of the project.

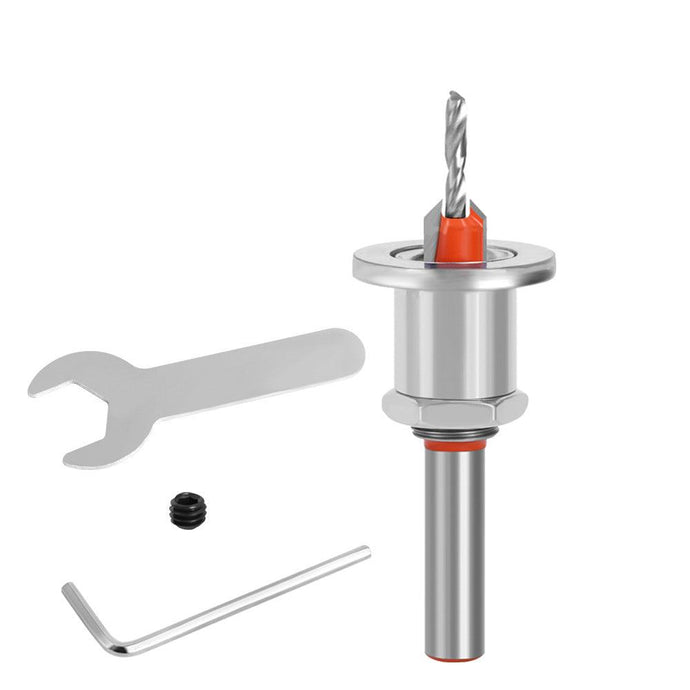

The shape of a countersink bit is quite different from that of a step drill bit. Rather than being tapered in steps, it features a sharp, conical cutting edge designed to shave away material in a smooth, angled fashion. The angle of the countersink bit is crucial because it needs to match the angle of the screw head being used, typically 82 or 90 degrees. This ensures that the screw will nest perfectly into the material, creating a secure and flush fit.

While step drill bits are focused on versatility and efficiency across multiple hole sizes, countersink bits are all about precision and aesthetics. The countersink bit isn't used to create holes of varying diameters but rather to refine and finish holes for screw installation. The result is a more polished and professional appearance, particularly in projects where visible screw heads would be a distraction or could interfere with the design.

Both step drill bits and countersink bits come in various materials and coatings, which can enhance their performance. For example, high-speed steel (HSS) is a common material for both types of bits, offering durability and heat resistance. Some bits are coated with titanium or cobalt for added strength and longevity, particularly when working with harder materials like metal. However, the choice of bit material largely depends on the project and the material you're working with. While an HSS countersink bit might be ideal for woodworking, you may want a carbide-tipped step drill bit for drilling through harder metals.

Another key difference is the type of shank each bit has. Step drill bits typically have a round or hex shank, allowing for easy attachment to a power drill. They are designed for drilling through thin materials, so their shanks are often optimized for quick and efficient drilling. Countersink bits, on the other hand, may have more specialized designs, including adjustable depth stops or pilot hole combinations, depending on the specific task at hand. Some countersink bits are designed to be used with hand drills, while others work best with power tools for increased precision.

In summary, the step drill bit and the countersink bit serve distinct purposes in the world of drilling and hole preparation. The step drill bit excels at creating multiple hole sizes quickly and efficiently, particularly in thin materials, while the countersink bit focuses on finishing pre-drilled holes for a smooth, flush screw installation. Both tools are invaluable for different tasks, and understanding when to use each will ensure your projects are completed with accuracy, professionalism, and ease. Whether you're working on a metal fabrication project or fine-tuning a woodworking piece, having the right drill bit on hand makes all the difference.